Snap-back area

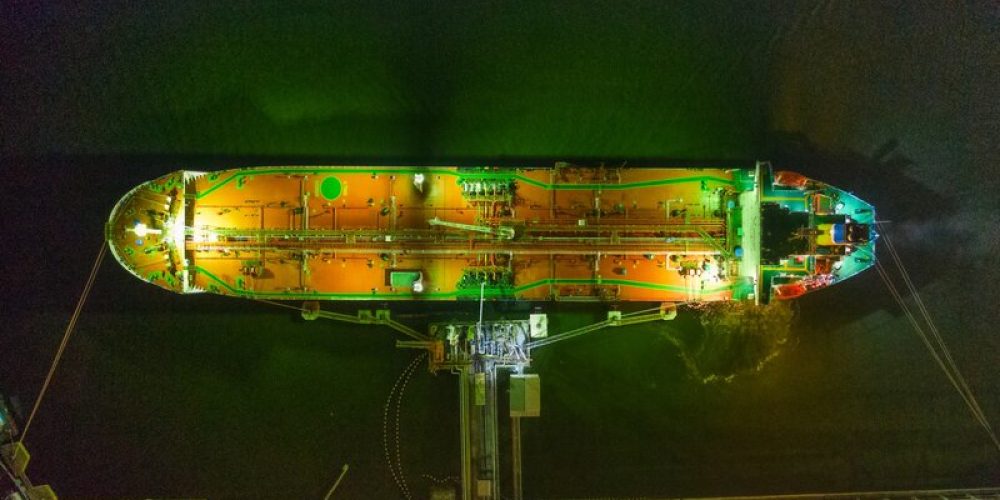

Our article How to purchase mooring lines and tails was addressed to the process of purchasing mooring lines and tails according to MEG-4 Guide. However, it is not enough to purchase correct lines. There are many factors affecting safety use of mooring lines. They are always subject to wear, tension, friction and temperature impacts and also manufacturing defects. They may stretch, particularly those made of synthetic material. When the line breaks two ends of this line recoil or snap-back towards and past the points to which they are secured.

According to West of England when a synthetic mooring line breaks, the snap-back effect can be extremely powerful and the rope ends may reach a velocity of up to 800 km/h (500 mph) as they recoil, with often lethal consequences to anyone standing in the snapback zone.

Different maritime Authorities reports that for the last 10 years dozens of deck crew members and terminal staff being located in snap back zone have been injured by parted lines.

It became common practice in recent years to mark snap-back zones in the vicinity of rollers, fairleads and near mooring machinery on ships deck. But industry knows the cases when crew member was injured when standing not in a place being identified as dangerous snap-back area.

The whole ships mooring deck may be considered a potential dangerous snap-back area. Same is recommended in the latest version of the UK Maritime and Coastguard Agency’s Code of Safe Working Practices for Merchant Seafarers (COSWP, 2019). Chapter 26 of the COSWP explains:

“26.3.2 Owing to the design of mooring decks, the entire area should be considered a potential snap-back zone. All crew working on a mooring deck should be made aware of this with clear visible signage.”

“26.3.3 The painting of snap-back zones on mooring decks should be avoided because they may give a false sense of security.”

Indeed deck crewmembers may have delusive sense of safety while they are not working in the designated snap-back zone. Isolation of slight areas around the mooring equipment does not map the actual snap-back area. Recent studies have shown that the nature of snap-backs is more complex than was interpreted initially. The following factors may influence while determining the snap-back effect:

- Mooring arrangements

- Technical characteristics of the mooring line

- Breaking strength of the mooring line

To ensure the mooring operation is carried out in a safety way and in accordance with the best industry practices at least, but not limited to, the following must be taken into consideration prior to mooring operation:

- the company’s safety procedures are followed in regards to mooring equipment and mooring lines condition

- on board risk assessments are conducted to ensure potential snap-back zones are identified

- mooring plan illustrates the identified snap-back hazardous areas

- all participating crew members are aware of the hazards of snap-back prior to mooring operations

- clear visible signs are displayed on ships deck to warn crew about dangerous areas

- persons not involved in the mooring operations directly must be kept away from the identified snap-back areas

Mooring lines manufacturers attempt to find a solution in order to mitigate snap-back effect. For example, Wilhelmsen Group invented their Snap Back Arrestor (SBA) to decrease snap back. This remarkable video demonstrates obvious difference when SBA is applied and when it is not.

Useful links: