If your Company supplies or provides an innovative product or services you can tell the shipping community about. Or if you have a Case Study you can share with the industry professionals and your potential clients here. Just send the information to info @ seavendors.com with title ARTICLE. Any questions? Contact us.

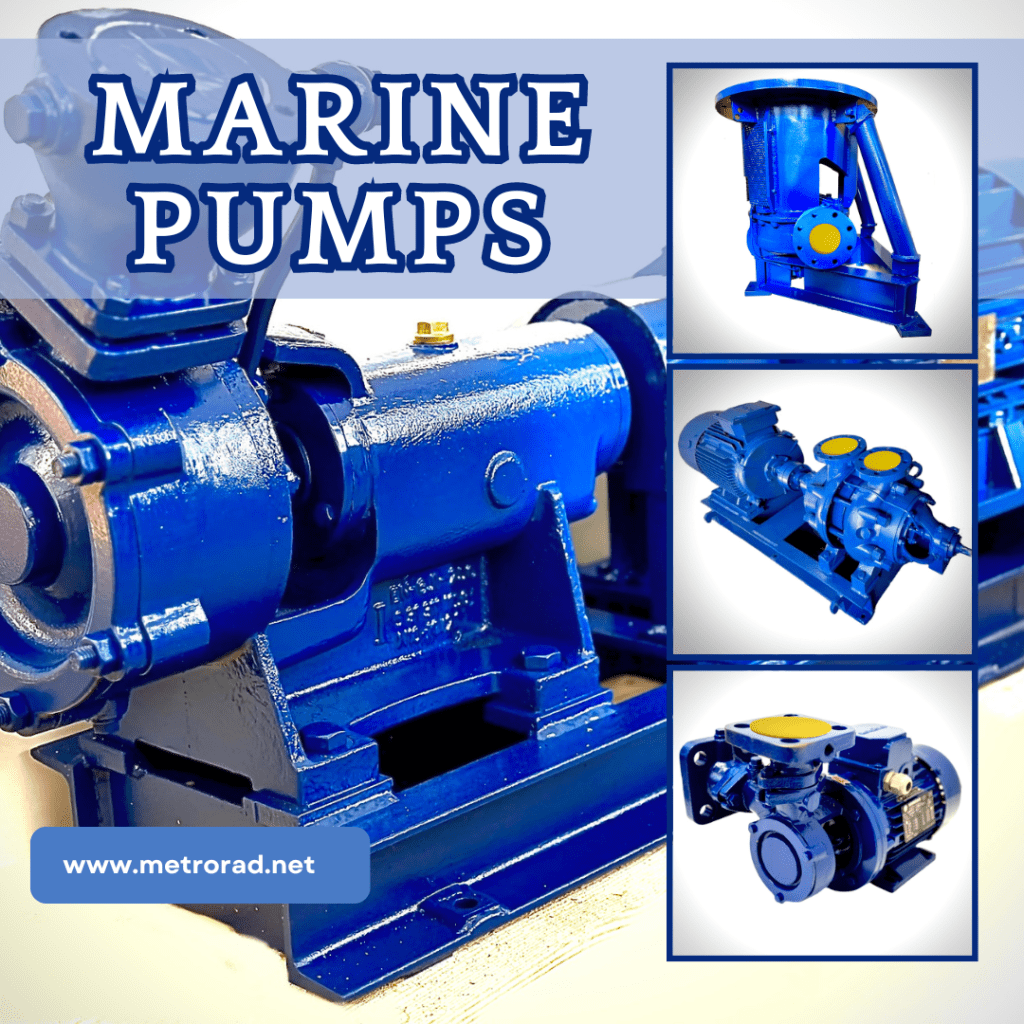

What you need to know about marine pumps

Marine pumps are decidedly commonplace on modern vessels. In fact, in some cases, they can account for up to 30% of the machinery of a ship. Some ships can require up to 50 pumps for optimum efficiency.

The reason for it is simple – ocean-faring vessels need marine pumps for some of their essential applications. The right marine pump ensures the ship’s efficient and safe operation and the crew’s safety. Not to mention that any engine room failure can negatively impact the vessel’s profits.

The definition of the marine pump

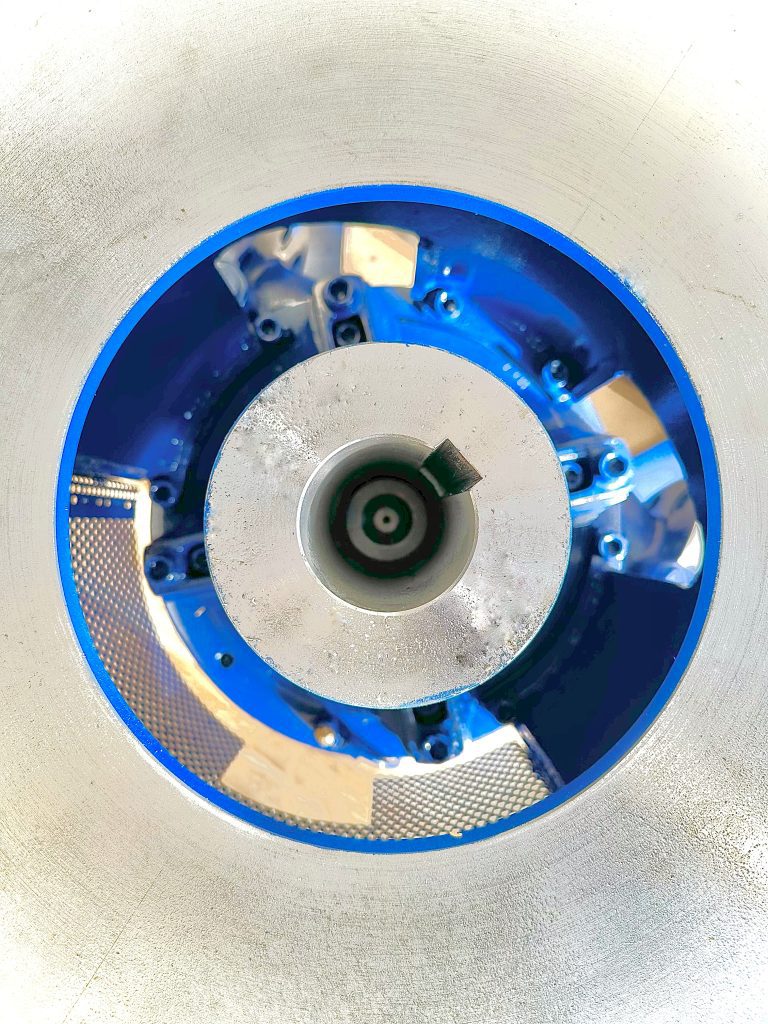

A marine pump is a mechanical device that circulates liquids through compartments and tanks on the ship.

Before picking out the right pump, you need to consider various factors.

Different types of ships (passenger ships, container ships, oil and gas tankers, offshore support vessels, for example) require different pump types.

Likewise, the type of pump used on a ship depends on its purpose and what kind of liquid it is supposed to circulate. The viscosity and density of the fluid, the temperature of the system, and the pressure of the fluid are also factors to consider.

Pumps can also be attached to the machinery or powered by the ship’s power supply.

The main types of marine pumps

Rotodynamic (or dynamic pressure) pumps

Rotodynamic pumps include axial flow, centrifugal, mixed centrifugal-axial, and submersible pumps. Rotodynamic pumps work by using lateral forces for their pumping action. The impeller usually accelerates fluids. It bears mentioning that some systems will also require a positive displacement pump for priming. Ships use rotodynamic pumps for systems that utilize low-viscosity fluids, have moderate to high discharge rates, and have low to moderate pressure differential range.

Positive displacement pumps

Positive displacement pumps include rotary and reciprocating pumps. Rotary pumps include screw and gear pumps, and reciprocating pumps include diaphragm and piston pumps.

Positive displacement pumps are self-priming. They work by enclosing the fixed volume. They consist of at least one chamber with the working parts of the pump moving and increasing and decreasing the working volume.

Positive displacement pumps produce high pressure, are used for small to medium discharge rates, and circulate high-viscosity fluids.

Things to consider when choosing the right pump for your ship

What is the primary application of the pump? What are the pump’s features and capabilities? These factors determine where the pump is best used.

What type of power source do you need for the pump? Hydraulic pumps need hydraulic fluid under pressure, while electric pumps need an electric power source.

Is the pump reliable and easy to maintain? Reliability and easy upkeep is one way to ensure long-term performance and optimum safety at sea. What type of flow rates do you need? Flow rates denote the amount of liquid that travels through the pump over time and indicate the best use for the marine pump.

More info: https://www.metrorad.net